AppleInsider is supported by its viewers and will earn fee as an Amazon Affiliate and affiliate associate on qualifying purchases. These affiliate partnerships don’t affect our editorial content material.

Apple is rumored to deliver OLED shows to the iPad Professional by 2024, manufactured utilizing a way known as dry etching to make sure the screens stay as skinny as attainable. Sadly, this will even possible make these iPads costlier. This is why.

If the report about OLED iPad Professional fashions is taken at face worth it may imply that Samsung can be a producer answerable for producing the shows. The corporate did provide OLED panels for the iPhone 12 and iPhone 13. Nevertheless, the report supplied no sources apart from saying “Apple confirms.”

Dry etching shouldn’t be new. The U.S. Patent Workplace granted a patent to Samsung in 2004 for a dry etching equipment.

The patent describes a vacuum chamber the place the etching takes place, a “chuck” that holds the substrate, and one other half known as a “baffle plate” that encloses the chuck and discharges the merchandise used for etching. Whether or not Samsung nonetheless makes use of this explicit equipment is unknown, however vacuum chambers are needed throughout the dry etching course of because of the plasma.

Kinds of etching

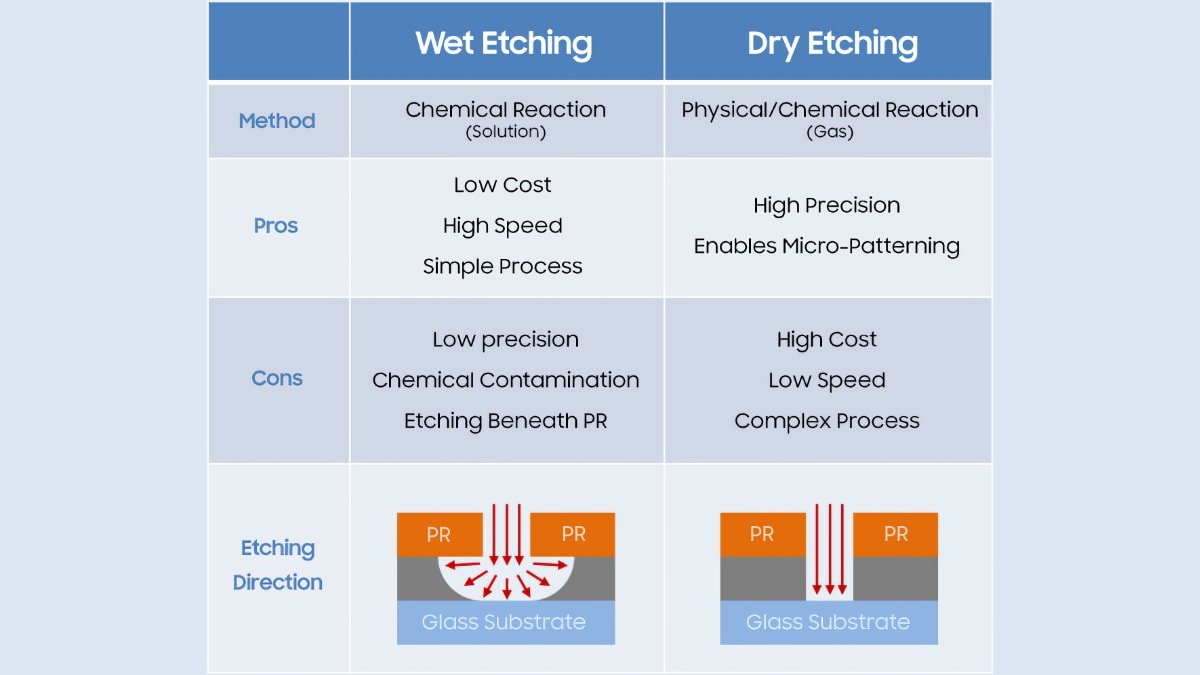

Samsung describes moist etching as low-cost, quick, and easy. Dry etching wafers is extra exact and fewer vulnerable to contamination however is dear and sophisticated. Thus, if Samsung makes use of this technique for producing OLED screens, it could improve the iPad’s worth.

Etching is a course of that removes undesirable materials from a wafer, which is often known as a “slice” or “substrate.” Wafers are made from semiconducting materials similar to crystalline silicon and are used within the fabrication of built-in circuits and photo voltaic cells.

Dry etching makes use of gaseous chemical compounds or plasmas to take away supplies from a wafer, whereas moist etching makes use of liquid chemical compounds, similar to solvents and acids. Each strategies have advantages and disadvantages.

Moist etching

A wafer is submerged in sure chemical compounds throughout moist etching, relying on its materials. For instance, buffered hydrofluoric acid is often used with silicon wafers.

Like all manufacturing course of, there are waste streams. Hydroflouric acid and the supplies dissolved within the run-off from manufacturing have to be appropriately disposed of to forestall water contamination. As well as, the solvent could take away extra materials from the wafer than is good.

Evaluating moist etching and dry etching

In Samsung’s chart, “Etching beneath PR” discovered underneath moist etching refers back to the photoresist, a fabric delicate to mild that modifications its properties throughout picture lithography. The result’s intricate circuits on the skinny movie transistor (TFT) that the show itself is utilized to.

Samsung and different producers use moist etching for Apple’s current OLED provide for the iPhone.

Dry etching

A producing different is dry etching, which is extra exact and may take away substrate supplies in numerous shapes than moist etching.

Dry etching is often utilized in very giant scale integration (VLSI) processes that produce built-in circuits. There are a couple of strategies in dry etching, similar to isotropic radial etching, reactive ion etching, sputter etching, and ion milling. The intricacies of every are past the scope of this text, and differ primarily based on how the method removes semiconductor supplies from the wafer.

All variants of dry etching processes use plasma, which is why dry etching is also known as plasma etching. Ion milling and sputter etching use a beam of ions to eject or vaporize materials bodily.

Samsung’s article describes plasma etching, the place fuel is injected into the vacuum chamber containing the wafers and energized to change into plasma. Then, ions that achieve excessive kinetic power are beamed onto the wafer to take away semiconductor materials.

A wafer and its circuitry earlier than, throughout, and after etching

In each varieties of etching, the photoresist acts as a protecting movie for the circuit sample throughout the etching course of. After etching, solely layers coated with PR for use because the circuit are left on the glass substrate. All different supplies are eliminated.

Manufacturing

Whereas dry etching is not strictly new, it is not utilized in a lot at current.

In 2021, Gerald Yin, chairman of Chinese language semiconductor tools firm AMEC, mentioned the corporate’s plasma etching tools was being utilized in a buyer’s 5nm chip manufacturing.

AMEC did not reveal the client, however on the time the one ones able to 5nm mass manufacturing had been TSMC and Samsung, two corporations which have served as producers for Apple. In June 2022, TSMC posted a job itemizing for a “Dry Etching Course of Engineering Supervisor” at its 5nm fab in Arizona.

Samsung’s patent says {that a} dry etching equipment utilizing plasma is appropriate for fabricating circuits with a width of 0.15 micrometers or much less. The corporate concludes that dry etching is the popular technique for high-resolution shows.

The Apple provide chain will possible hold utilizing the moist etching course of for iPhone and Apple Watch. It is a cheaper resolution that produces a show nonetheless lighter than an LED display screen with the next high quality, at a comparatively low worth.

Dry etching is healthier merchandise with giant OLED shows. The method prices extra however its precision is useful for these giant shows the place weight is an element.