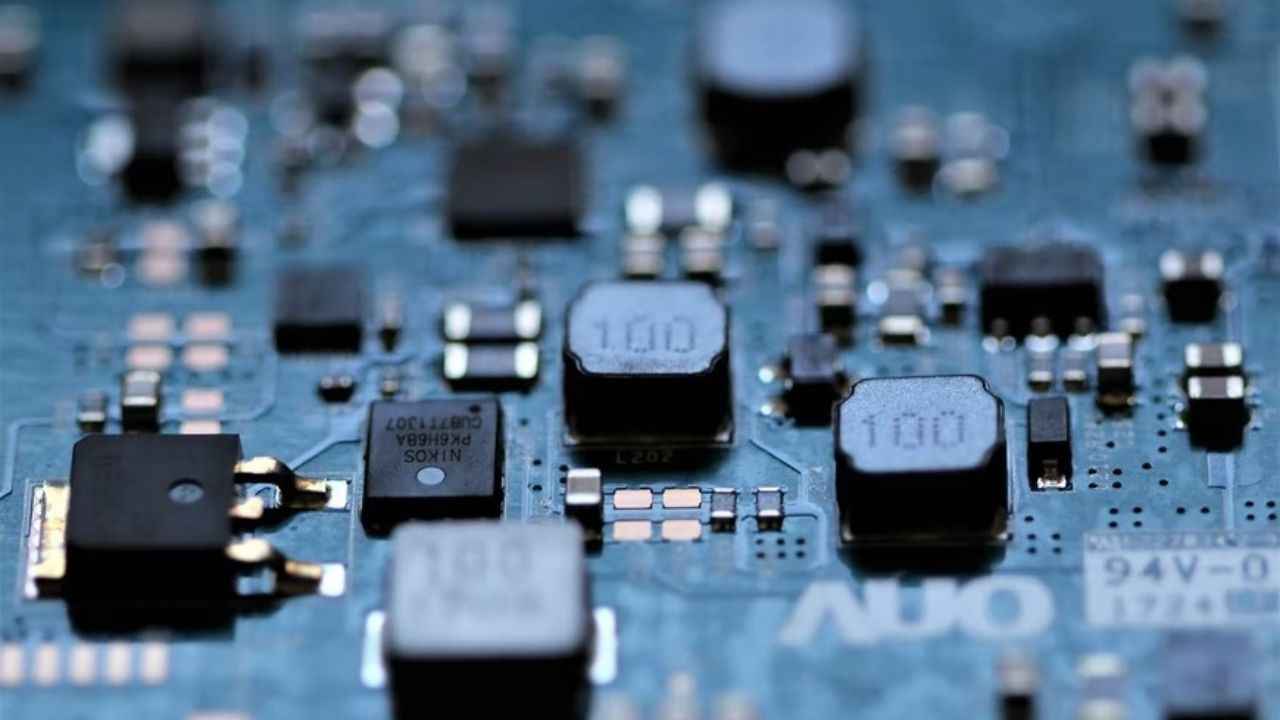

The scarcity of semiconductor chips that goes into varied objects to normalise someday in subsequent 12 months whereas the lead occasions proceed at a better degree, Moody’s Analytics stated in a report.

“Whereas we see lead occasions remaining elevated by way of the tip of the 12 months, we count on the chip scarcity to normalise someday in 2023,” stated the report.

In accordance with Moody’s Analytics, final month was the primary time because the begin of the pandemic the lead time fell from 27.1 weeks to 27 weeks.

“Whereas the decline is notable given the upward pattern in lead occasions prior to now couple of years, 27 weeks remains to be removed from the norm, and we count on lead occasions to stay elevated going into 2023,” the report notes.

Creating new provide for chips is a multiyear course of and includes important time and sources to construct a brand new foundry/plant.

There’s additionally important lead time in acquiring the lithographic machines wanted to make the chips themselves.

In accordance with the report, contemplating the chip scarcity, many corporates resorted to ordering greater than they wanted, leading to extra stock.

On the core of the chip scarcity is the truth that many of the world’s superior chips (measurement 7 nano metre, or nm, and fewer) aremanufactured in Taiwan and South Korea, and there are important entry prices to penetrate this market, stated the report.

“To place this in perspective, China has spent greater than $10 billion over the previous decade investing in its semiconductor business, and its largest producer solely lately introduced that it’s lastly in a position to produce 7nm chips, although the frontier has already moved to a lot smaller chip sizes,” the report notes.

Even for corporations just like the Taiwan Semiconductor Manufacturing Co. and Samsung it takes years earlier than they can construct a brand new foundry, or plant for making chips.

That aside, the geopolitical scenario can also have an effect on semiconductor manufacturing.

In accordance with Moody’s Analytics, China has restricted sand exports to Taiwan following the go to of Speaker of the US Home of Consultant, Nancy Pelosi to Taiwan. China might limit different exports crucial to chip manufacturing if the scenario escalates.

The opposite geopolitical occasion that has important ramifications for the chip scarcity is the Russian invasion of Ukraine.

Each international locations are important producers of neon, palladium, helium and different inputs necessary for chip manufacturing. The explanation this has not disrupted the chip provide chain extra radically is as a result of some chipmaking corporations have lithographic machines that recycle greater than 80 per cent of the neon and noble gases utilized in manufacturing. It stays to be seen whether or not it will have a extra materials impression if the navy battle persists.

Moody’s Analytics see some divergence within the demand and provide stability for varied chip purposes. Chips used for networking, optimum and telecommunications gear are in brief provide field-programmable gate arrays have lead occasions in extra of fifty weeks.

Against this, microcontroller items in addition to energy and reminiscence chips have seen among the largest declines in lead occasions.

“We count on lead occasions and costs for reminiscence purposes to stabilize, however can see costs and lead occasions rising for discrete and analog purposes if the aforementioned manufacturing pressures proceed,” Moody’s Analytics stated.

(Aside from the headline, the remainder of this IANS article is un-edited)

For extra know-how information, product opinions, sci-tech options and updates, hold studying Digit.in.