In context: The largest distinction between constructing {hardware} and software program is the period of time it takes to get to first income. There are not any straightforward methods to shorten this, however there are methods to adapt and ease the trail to income development.

We clearly have sturdy biases on the subject of the advantages of investing in {hardware} versus investing in software program. And we’ve got some sturdy opinions on the funding instances for every being rather more comparable than the frequent knowledge holds. Nonetheless, there are apparent variations between the 2, and we wish to discover these variations with the top objective of discovering methods to de-risk {hardware} investing, or the least, discovering lodging to degree out long-term outcomes.

Editor’s Word:

Visitor writer Jonathan Goldberg is the founding father of D2D Advisory, a multi-functional consulting agency. Jonathan has developed development methods and alliances for corporations within the cellular, networking, gaming, and software program industries.

Unquestionably, one of many largest advantages of beginning a software program firm is how shortly an organization can get to income. The proverbial two engineers in a dorm room can construct an actual product and get to income nearly actually in a single day.

The world of {hardware}, particularly semis, could be very totally different. In reality, if we needed to identify the one most essential distinction between the 2 it comes right down to timing.

Constructing {hardware} simply takes time. Design the product, re-think the design, construct a prototype, repair the errors, redesign, construct for manufacture, then enter intro manufacturing. There are only a lot extra steps concerned, and often lots of these steps are depending on different corporations additional including to the time.

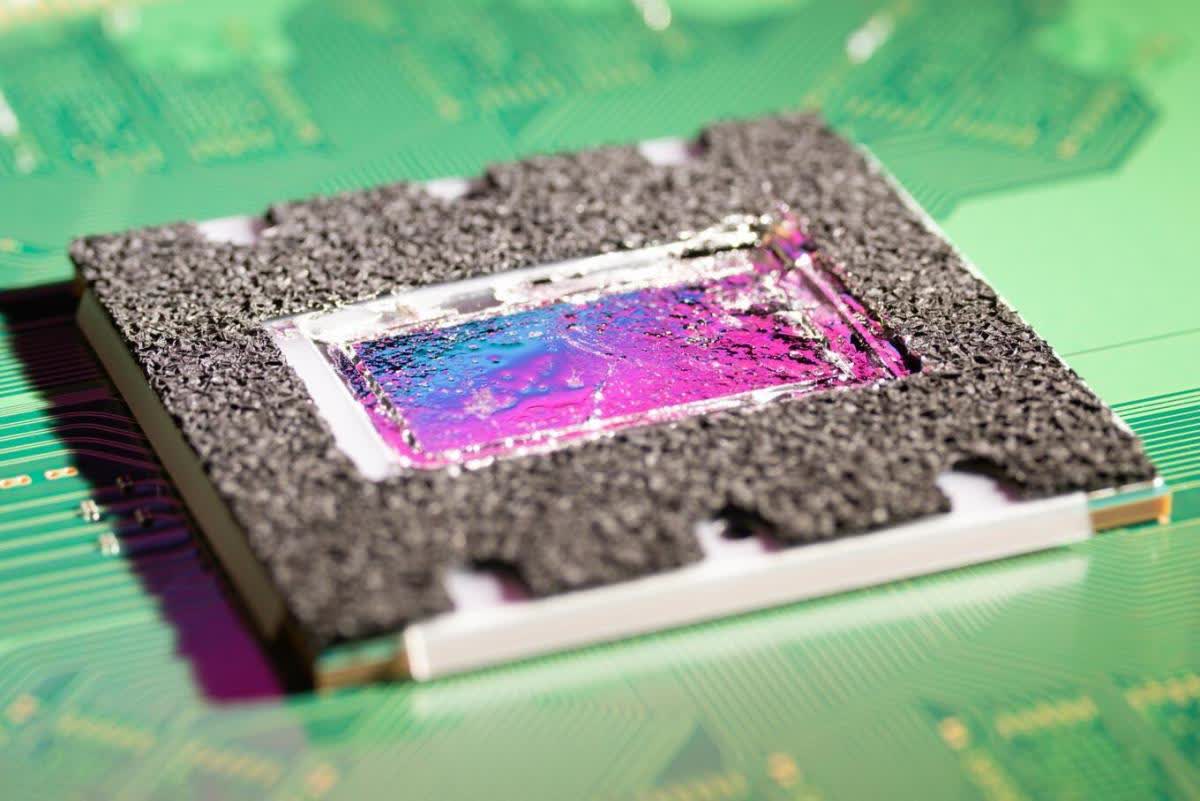

Take the instance of a semiconductor. We not too long ago labored with a workforce of 20. They designed their chip in slightly below six months. This was an extremely seasoned workforce and so there have been no doubts that their design would work. Then they needed to spend a month plugging their knowledge into TSMC’s software program interface (a.ok.a. the PDK). They despatched their libraries and TSMC ‘taped-out’ their chip and three months later, they received first silicon again and needed to undergo a number of extra months of testing and packing.

All collectively a few yr from serviette to first working pattern. Word that over half the time was taken by outdoors events. For these not accustomed to semis design this seems like an excruciatingly very long time. These accustomed to semis design will probably be amazed at how fast this workforce moved. Critically – 20 individuals in below six months! This was not a small chip both.

There are not any straightforward methods round this. Software program might be patched in real-time, however as soon as {hardware} goes out the door there is no such thing as a approach to repair it.

So the query then turns into easy methods to cope with this actuality.

For one, it has grow to be slightly simpler to construct prototype chips. There are a rising variety of “Free Tape Out” packages, with many trailing edge foundries providing low cost pricing for small runs. For bigger, process-dependent chips, emulation on FPGAs works pretty effectively. This isn’t excellent as clients won’t commit till they see working silicon, as a result of they are going to wish to run their very own evaluations (and don’t get us began on how lengthy the entire EVT/PVT/DVT cycle can take). However these strategies can a minimum of exhibit to traders and clients that the product has one thing to supply.

One other essential adaptation will probably be to shift to a “answer” sale, wherein corporations promote some type of service on prime of the chip. This could be a full {hardware} module (with chips and a board) or more and more it may possibly imply software program operating on the chip. We have now written on this topic previously. It’s tough to realize however has advantages.

The perfect could be for a chip firm to design a regular product whose options might be enhanced by way of periodic software program updates. That is firmly within the camp of “If you cannot beat them be part of them”, borrowing a web page from software program corporations. This doesn’t get to first income sooner, however it does pave the way in which for incremental gross sales, easing the trail to development.

The impediment to this path is that it actually entails a completely new enterprise mannequin, not only a new product. The semis trade is basically constructed on habits of product gross sales, however this mannequin requires a “answer sale,” which most large chip corporations aren’t outfitted to supply.

None of this can shorten the time to income a lot, however it does present a reasonably strong adaptation. And never for nothing, offers everybody one thing to do whereas ready for first silicon to come back again from the foundry.