Lawrence Jengar

Oct 18, 2024 02:33

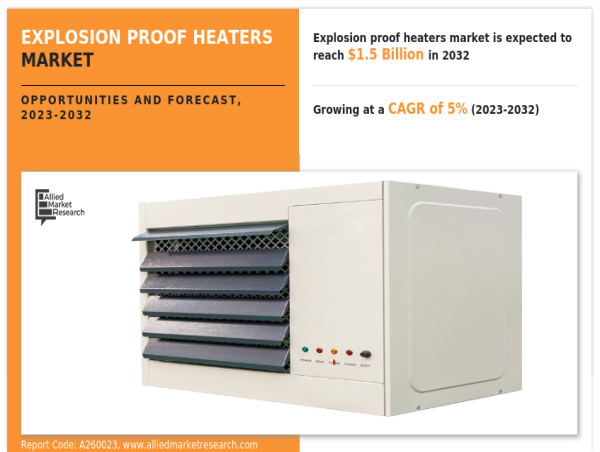

Siemens and NVIDIA leverage digital twins to boost sustainable manufacturing, lowering emissions and optimizing processes by superior simulations and real-time knowledge integration.

In a major stride in the direction of sustainable manufacturing, Siemens and NVIDIA are pioneering the usage of digital twins to optimize manufacturing processes and cut back carbon emissions. This progressive method is a part of a broader effort to enhance the sustainability of producing cycles, from materials sourcing to end-of-life disposal, in keeping with the NVIDIA Weblog.

Key Challenges in Sustainable Manufacturing

Balancing sustainability with profitability stays a problem for producers. A 2022 examine by Ernst & Younger highlighted that digital twins may cut back development prices by as much as 35%, indicating a powerful hyperlink between useful resource consumption and bills. Nonetheless, departmental silos and knowledge administration points nonetheless pose vital hurdles.

Many producers battle to harness huge knowledge assets successfully, impacting their sustainability targets. A examine by The Producer revealed that knowledge inefficiencies negatively affect vitality effectivity and sustainability, with knowledge usually siloed to native use circumstances.

The Position of Digital Twins in Sustainable Manufacturing

Digital twins, powered by platforms like NVIDIA Omniverse, are reworking the manufacturing panorama. By contextualizing engineering knowledge, digital twins present a complete view that enhances collaboration throughout departments. This expertise permits for the simulation and optimization of designs and processes, minimizing waste and errors.

Siemens is integrating NVIDIA Omniverse APIs into its Xcelerator platform, enabling corporations to create detailed digital twins for higher useful resource administration. Firms like HD Hyundai are leveraging these capabilities to visualise complicated engineering knowledge, enhancing their sustainable manufacturing efforts.

Equally, Foxconn has developed a digital plant utilizing digital twins to optimize its manufacturing processes. By simulating manufacturing unit environments, Foxconn goals to enhance automation and effectivity, anticipating a 30% discount in annual vitality consumption.

Making Each Watt Rely

With the rising demand for AI, industries are challenged to steadiness vitality effectivity with AI development. Accelerated computing platforms, integrating GPUs and CPUs, supply an answer by enhancing computational effectivity and lowering vitality use. These programs have demonstrated as much as 20x extra vitality effectivity in AI duties in comparison with conventional CPU programs.

Producers can additional cut back their environmental affect by vitality administration methods, together with renewable vitality sourcing and progressive practices like warmth reuse.

The Way forward for Sustainable Manufacturing: Industrial Digitalization

The subsequent part in manufacturing is the commercial metaverse, the place digital and bodily realms merge. This evolution will permit for extra immersive digital twins, enabling sooner, data-driven selections. Siemens’ CEO Roland Busch emphasizes the potential of those developments to revolutionize product design and manufacturing.

Main the Method With Digital Twins and Sustainable Computing

The collaboration between Siemens and NVIDIA exemplifies the potential of digital twins and accelerated computing in lowering manufacturing’s environmental affect. Via superior simulations and AI insights, producers are poised to realize better vitality effectivity and lowered waste on their path to decarbonization.

Picture supply: Shutterstock