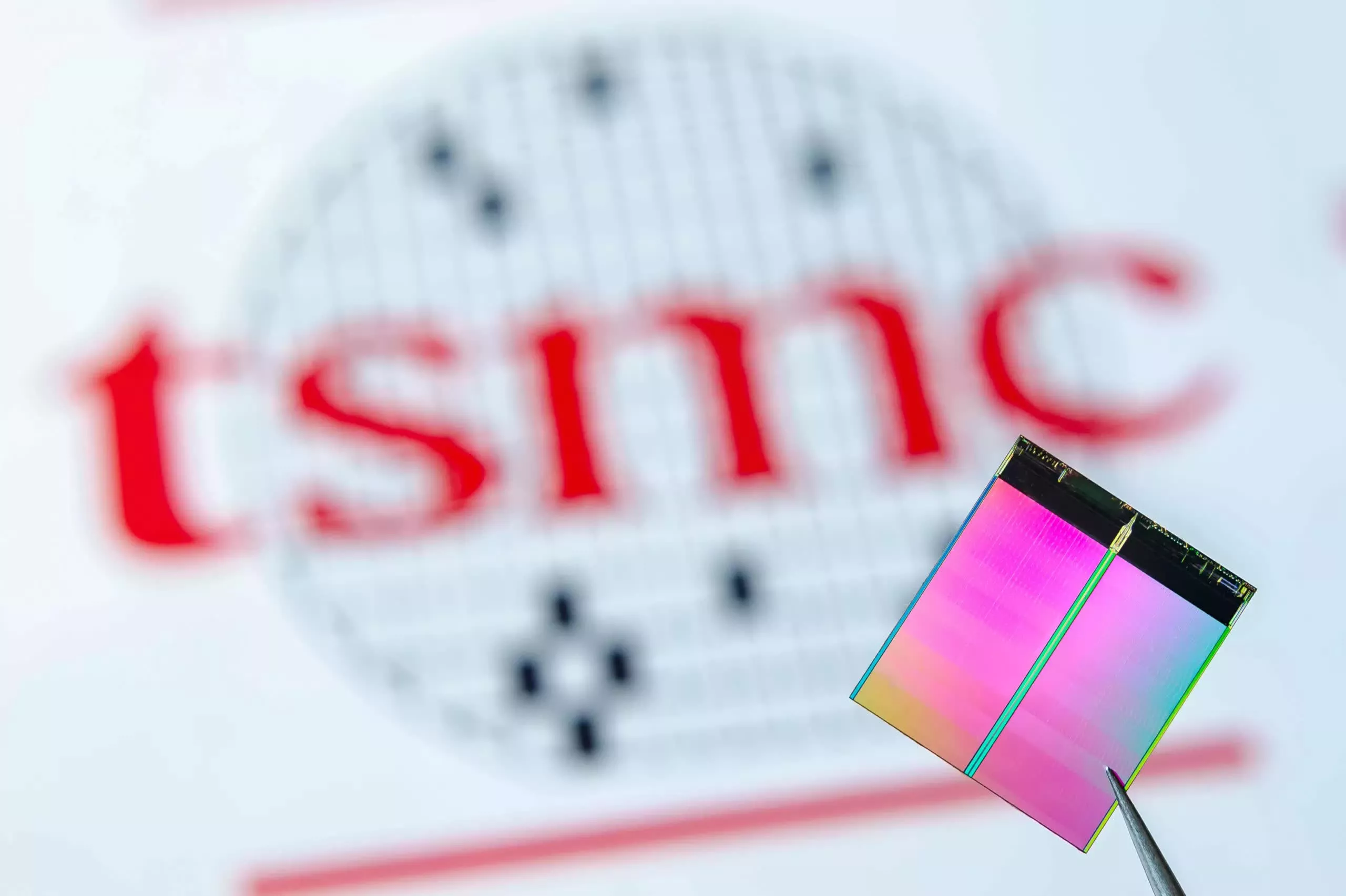

In short: We’re in the midst of a world financial slowdown that has hit tech corporations particularly arduous, however it appears no person informed TSMC. The world’s largest contract chipmaker noticed its November income improve 50.2% year-on-year to achieve $7.27 billion, and a variety of it was because of Apple.

Falling demand, China’s Covid Zero insurance policies, the rising price of dwelling, and recession fears have made 2022 a nasty 12 months for tech giants. Demand for the whole lot from smartphones to PCs has fallen, and mass layoffs have grow to be a daily sight.

TSMC has bucked the pattern by greater than doubling its gross sales in November—in comparison with a 12 months earlier—reaching $7.27 billion. That places the corporate on monitor to hit its fourth-quarter estimate of between $19.9 billion and $20.7 billion.

A lot of TSMC’s good quarter got here from supplying the A16 SoC used within the iPhone 14 Professional and 14 Professional Max. Apple, already TSMC’s largest buyer, mentioned final month that it might buy chips from the provider’s US services, lessening Cupertino’s reliance on Asia. We additionally heard that the Taiwanese big will start manufacturing on a 4nm course of in its Arizona fabs in 2024—an improve from the beforehand deliberate 5nm wafers—following a choice that was reportedly inspired by Apple.

Some analysts wonder if TSMC will be capable of preserve its run of fine fortune going subsequent 12 months when orders might decline. Nevertheless, the corporate reportedly plans to boost 3nm wafer costs by 25 p.c over 5nm to $20,000, which ought to increase its backside line. The 2023 iPhone 15’s A17 Bionic chip shall be manufactured on the 3nm course of, and Apple has already agreed, albeit reluctantly, to TSMC’s value hike.

At an occasion attended by Joe Biden earlier this week, TSMC confirmed it might develop its constructing and manufacturing efforts throughout the US. The enlargement will see $40 billion spent on two fabs in Arizona, a rise from the beforehand deliberate $12 billion funding. The positioning will create tens of hundreds of jobs and have a complete manufacturing output of 600,000 wafers per 12 months.