It’s been some time since 3D printers grew to become out there and began permitting individuals to create 3D objects in the actual world proper from their very own house.

In case you’re enthusiastic about getting a rundown of what 3D printers are, how they work, how a lot they price, and what you would do with them, you’ve come to the precise place.

What’s a 3D printer?

A 3D printer is a tool that may create bodily objects from a digital file. The result’s often plastic. It might need tough edges and is commonly a single coloration. Regardless of these limitations, holding a real-world copy of a 3D mannequin makes it simpler to get a way of what works and what doesn’t.

One of the best 3D printers can create elements which are sturdy sufficient for on a regular basis use. The long-term aim of the trade is to increase the lifetime of shopper merchandise, permitting anybody to print an important substitute half that the producer now not retains in inventory.

Whereas recreating a lacking or damaged half is helpful, a 3D printer can even create sufficient elements to assemble complete merchandise. This know-how is nice for speedy prototyping, permitting fast modifications to refine the design earlier than committing to costly injection molds for high-volume manufacturing.

And 3D printing additionally has a spot in industrial manufacturing. When producing a small variety of merchandise, high-quality, however comparatively sluggish and costly 3D printing of elements generally makes extra sense than conventional strategies with excessive preliminary prices and a low price per unit.

How do 3D printers work?

The commonest 3D printer design, Fused Deposition Modeling (FDM), is much like an inkjet printer. The FDM printhead strikes aspect to aspect, depositing materials on a shifting platform. Whereas an inkjet printer sprays drops of ink on paper, a 3D printer extrudes sizzling plastic onto a glass or steel construct plate.

Two computer-controlled motors direct the movement of plastic alongside the size and width of the completed object, one for the printhead and one other for the construct plate. To create peak, a 3rd motor raises the rail the printhead slides throughout.

On the detrimental aspect, 3D printing is a sluggish course of in comparison with conventional manufacturing strategies, generally taking hours to construct an object up into the third dimension. You may make it sooner by extruding extra materials without delay, however that will increase layer peak and leads to a print that feels tough. Vertical curves and angles even have steps as a substitute of the graceful surfaces and flat planes of most manufactured merchandise.

The second-most standard shopper 3D printer kind makes use of gentle as a substitute of warmth to kind shapes in plastic. Generally known as a resin 3D printer, this sort makes use of UV gentle to mission a picture onto liquid resin that reacts to that wavelength and solidifies.

Resin 3D printing is commonly faster, curing a complete layer without delay. Nonetheless, UV resin often isn’t as sturdy because the thermoplastics used for FDM 3D printing.

Particular FDM filaments embrace extra sturdy plastic, in addition to a number of varieties of steel, glass, ceramic, and even wooden. The 3D printer half takes on look and a few of the traits of these supplies. With specialised 3D printers, it’s doable to create objects in quite a lot of supplies, even cheesecake.

What can a 3D printer make?

Business 3D printers could make nearly something. Some 3D printers use highly effective lasers to soften steel, creating sturdy elements to be used in rockets and different rugged equipment.

Shopper-grade 3D printers are restricted in dimension and supplies. The dimensions of the construct plate determines the utmost size and width of a component, whereas the peak of the printer impacts how tall a 3D-printed object could be.

Normally, 3D prints will match within the palm of your hand. Bigger shopper 3D printers can deal with objects somewhat over a cubic foot. It’s additionally doable to make a big object by assembling a number of smaller elements.

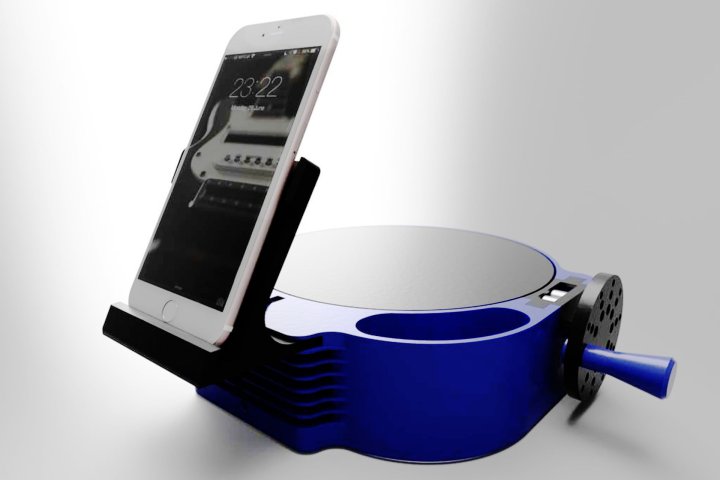

Among the hottest 3D objects embrace a whistle, a cellphone holder with a handbook turntable for scanning objects in 3D, a intelligent digital sundial that makes use of daylight to solid a shadow that tells the time in easy-to-read digits, and a mini octopus with versatile hinged legs that requires no meeting.

The chances are limitless. For instance, Thingiverse is among the largest libraries of 3D objects designed for 3D printing, with over 2.5 million digital information — and most are free.

With the rise of generative AI, it’s now doable to create 3D objects with textual content prompts. At current, AI isn’t creating designs optimized for 3D printing, so that you would wish to transform the file to a suitable format and course of it by means of a 3D-printing app earlier than use.

How a lot do 3D printers price?

You should purchase 3D printers beginning at about $100, an unimaginable discount for such highly effective know-how. Extra superior fashions have bigger construct plates and sooner print speeds, however price extra.

For round $300, you will get an excellent shopper 3D printer. In case you change into an fanatic who prints typically, $500 to $1,000 will get you a a lot sooner and bigger 3D printer. Business 3D printers vary from just a few thousand {dollars} to over $1 million.

Bear in mind you’ll want provides and would possibly need equipment to your 3D printer, so maintain somewhat extra within the price range for these added prices. FDM filaments and UV resin are comparatively cheap, however are bought in bulk, so that you’ll spend no less than $20 to get the mandatory provides.

Equipment embrace an enclosure to scale back the noise of an FDM 3D printer, higher construct plates, cooling followers to permit sooner printing, UV lights to harden resin, and instruments for 3D printer cleansing and upkeep. You often don’t want equipment to get began, and a few 3D printers include a small quantity of filament or resin to create the primary few prints.

A 3D printer unlocks the potential to inexpensively create substitute elements, duplicate designs which are out there on-line, or prototype completely new merchandise that don’t but exist. This unimaginable know-how has been round for decade,s however solely grew to become reasonably priced and straightforward to make use of in the previous couple of years.

In case you haven’t explored 3D printing lately, it’s time to take one other look. In case you’re new to 3D printing, now is a good time to get began.

Editors’ Suggestions